Low Weight Loss Magnet

It is the time for low weight loss neodymium magnet now!

The corrosion resistance of Neodymium magnet is considered poor, surface coating is highly recommended for Neodymium magnets. With the expansion of elevators, wind turbines and permanent motors application, the users need higher requirement on corrosion resistance of Neodymium magnet, as the glue cohesiveness of un-plated magnet is much better than plated magnets, also un-plated products are better in the security.

Now, more and more customers tend to use un-plated magnets, upon this condition we have developed ultra-low weight loss magnets after the continuous innovation and study. Normally, the weight loss test is over 150mg/cm² in the industry of Neodymium magnet, this will be different for magnets produced from different material formulation and manufacturing process.

A lot of our new magnets can reach to 1mg/cm², (Testing condition: HAST standard for 168hrs), due to its very low weight loss, the corrosion resistance is excellent, while the reliability and working life are greatly improved obviously.

The type of magnet can meet the strict requirements of corrosion resistance, low weight loss magnet is mainly used in elevator, radar, wind generators, military aerospace, industrial motors and other fields.

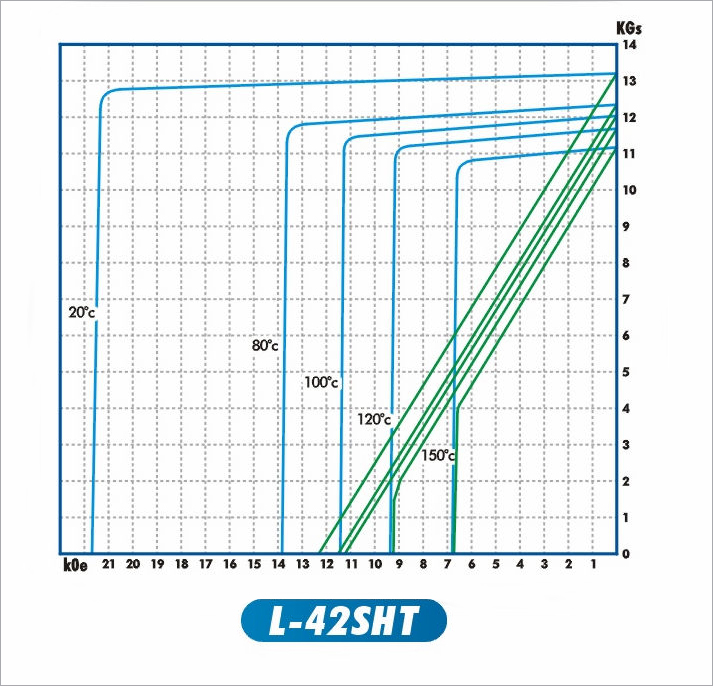

Here are two standards of low weight loss magnet:

1. US Standard: PCT (121℃±1℃), 2 atm, 95%RH, for 96 hours, weight loss less than 5-10mg/cm2.

2. EU Standard: HAST (130℃±2℃), 3 atm, 95%RH, for 168 hours, weight loss less than 2-5mg/cm2.